Hygienic Pumps

Viking Pump'shygienic pumps offer the best efficiency and a wide range of porting, cleaning, and sealing options to meet your needs. In a business where cleanliness is key to reducing cross-contamination, we offer CIP (clean in place), SIP (sanitize in place), and COP (clean out of place) pumps to save you time and effort.

Low Shear, Gentle Handling Liquid Pump

Low shearing and gentle handling of a wide variety of liquids, including suspended solids, are at the top of our minds when manufacturing our rotary lobe and circumferential piston pumps. Non-contacting surfaces of the rotary lobes limit wear over time regardless of the viscosity of the liquid; circumferential piston pumps offer high-pressure capabilities and low shear, keeping your product intact and flowing efficiently.

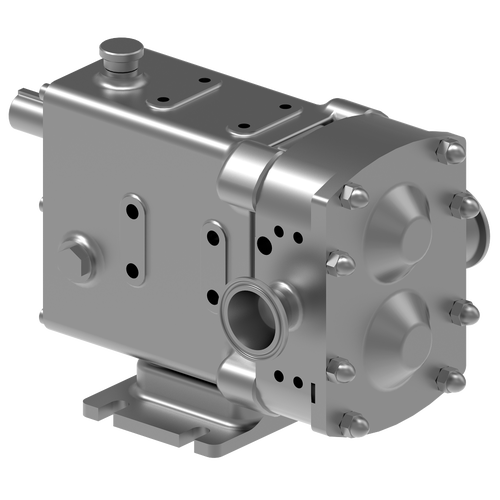

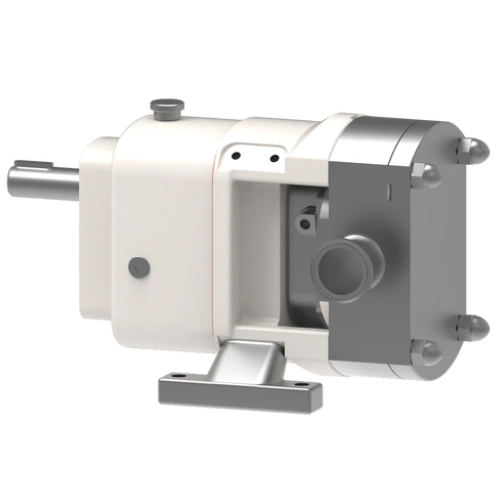

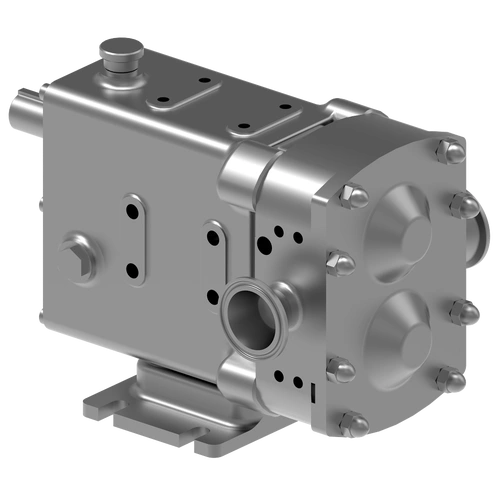

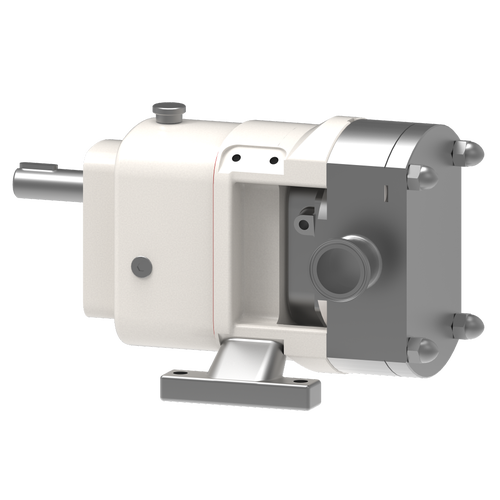

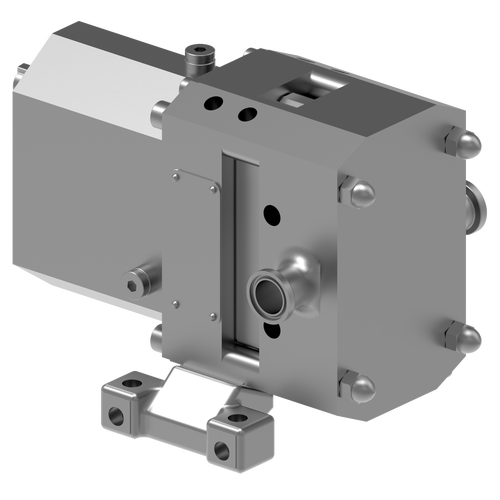

Circumferential Piston Product Line

Stainless Steel

Mechanical Seal, O-Ring Seal

Stainless Steel

Mechanical Seal, O-Ring Seal

0-450 GPM

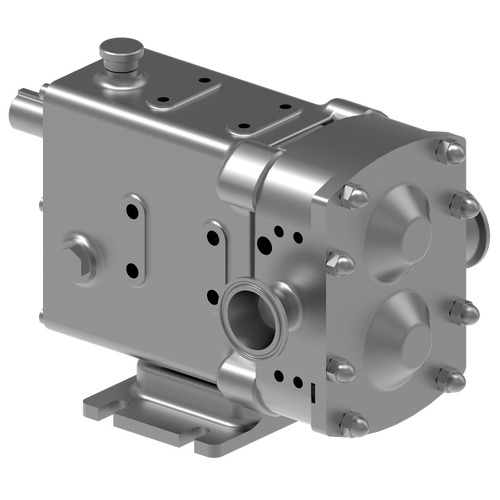

Stainless Steel

Mechanical Seal

0-450 GPM

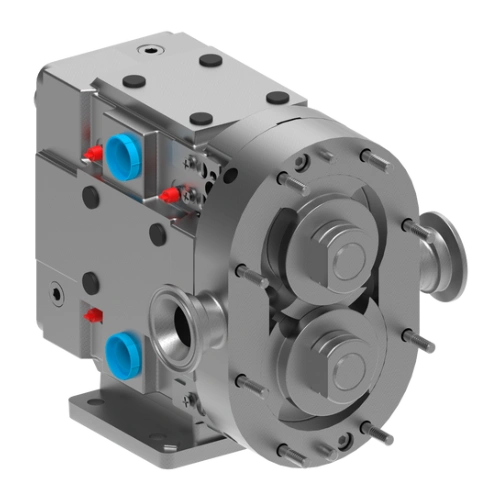

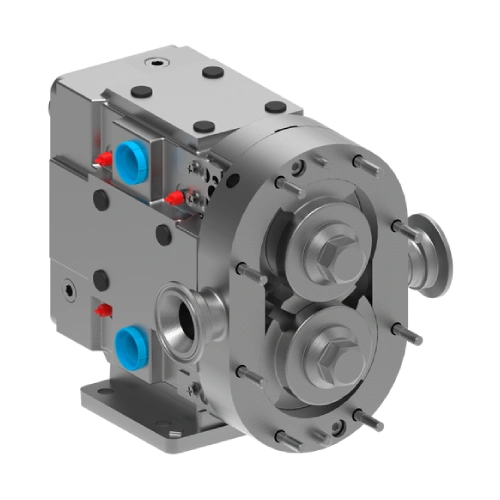

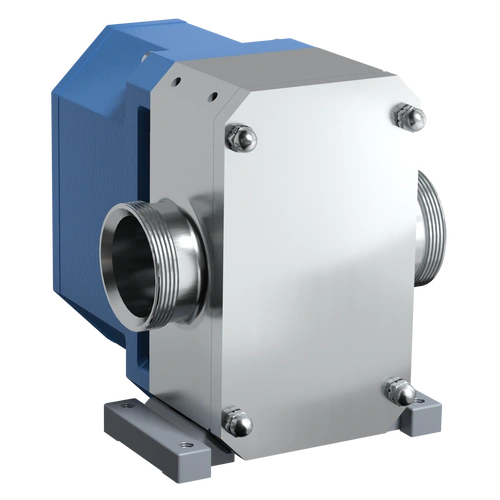

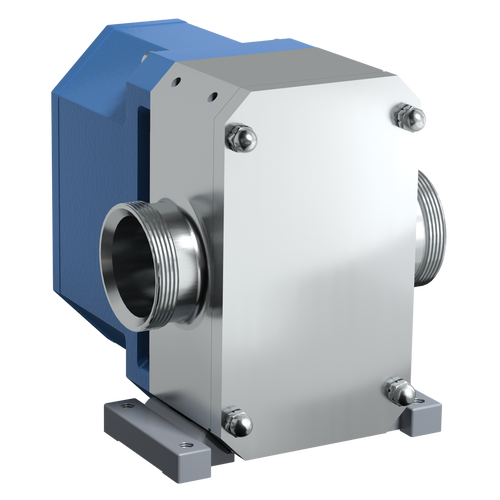

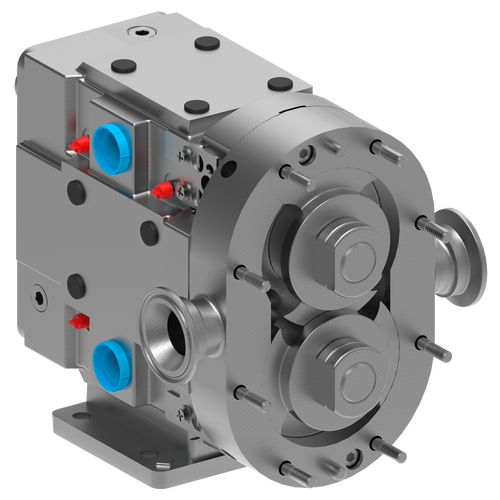

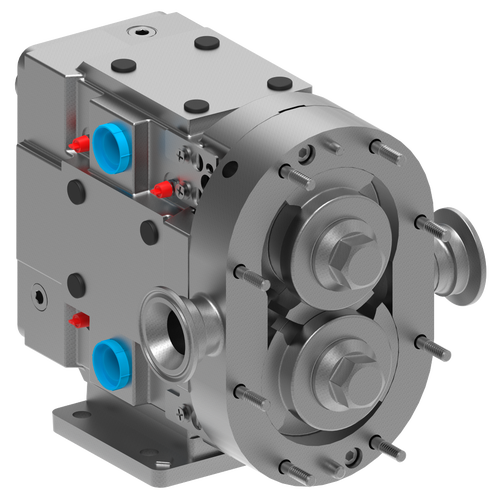

Rotary Lobe Product Line

Stainless Steel

Mechanical Seal

0-832 GPM

Stainless Steel

Mechanical Seal, O-Ring Seal

Stainless Steel

Mechanical Seal, O-Ring Seal

0-338 GPM

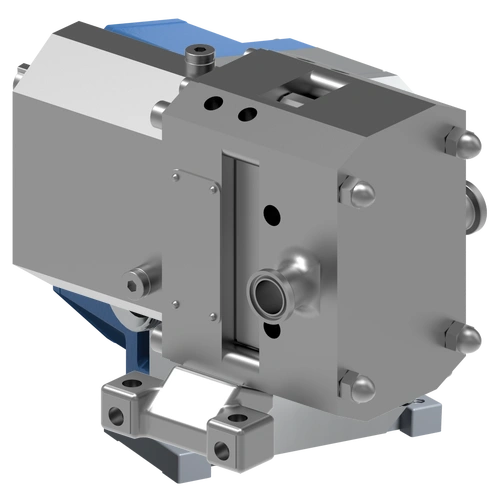

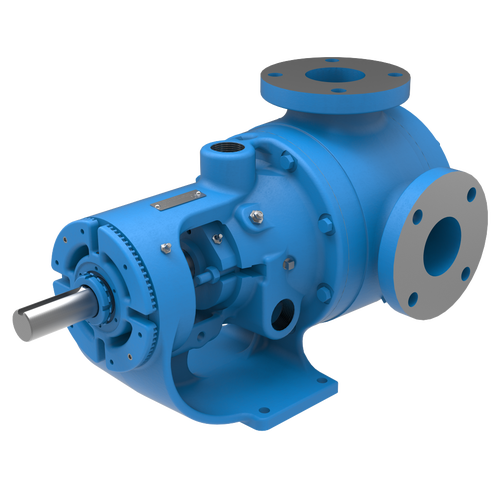

Liquid Specific

Cast Iron

O-Pro® Seal, Chocolate

0-400 GPM

Stainless Steel

Chocolate, O-Pro® Seal

15-335 GPM

Stainless Steel

Mechanical Seal

0-832 GPM

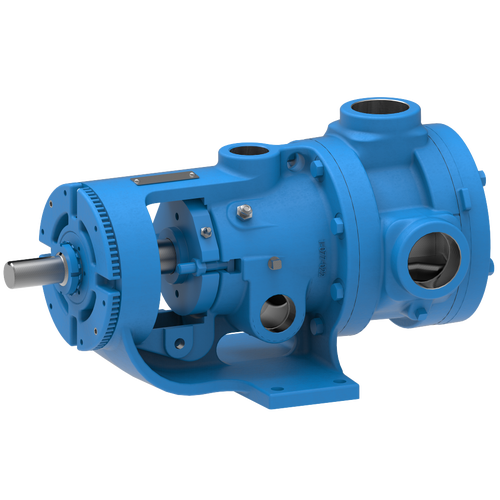

Stainless Steel

Mechanical Seal, O-Ring Seal

Stainless Steel

Mechanical Seal, O-Ring Seal

0-338 GPM

Stainless Steel

Mechanical Seals

0-753 GPM

Stainless Steel

Mechanical Seal, O-Ring Seal

0-450 GPM

Stainless Steel

Mechanical Seal

0-450 GPM

Formerly Wright Flow Technologies and Johnson Pump UK

In 2021, Wright Flow Technologies merged with Viking Pump to form Viking Pump Hygienic. Under this new name, Viking Pump Hygienic will continue to offer quality gear pump products to meet your application requirements. Backed by an engineering team with decades of experience, Viking Pump Hygienic looks forward to continuing this high standard in the future. Read more...

Superior Chemical Transfer Pumps

The stainless steel construction of our rotary lobe and circumferential piston pumps make them excellent pump solutions for chemical conveyance. Stainless steel holds up longer to challenging chemical transfer applications such as alcohols, acids & bases, and soaps & detergents.

Certifications

3-A Sanitary Standards, Inc. (3-A SSI) is an independent, not-for-profit corporation dedicated to advancing hygienic equipment design for the food, beverage, and pharmaceutical industries. 3-A SSI represents the interests of these three stakeholder groups with a common commitment to promoting food safety and the public health regulatory sanitarians, equipment fabricators, and processors. Viking Pump Hygienic has achieved 3-A certifications across our product lines and is actively involved in 3-A standards development.

The CE marking symbolizes the conformity of Viking Pump Hygienic's products with the applicable European Union (EU) legislative requirements as stated in the Machinery Directive 2006/42/EC. The CE marking affixed to Viking Pump Hygienic's products is a declaration of our product's conformance to all applicable EU provisions and the successful completion of the appropriate conformity assessment procedures.

The ATEX (EX) certifications indicate that our Hygienic pumps are in line with the applicable European Union (EU) legislative requirements in addition to those required by Machinery Directive 2006/42/EC for CE marking. The ATEX Directive applies to pumps intended for use in potentially explosive atmospheres, including when pumping flammable liquids or having flammable materials onsite. The EX marking affixed to Viking Pump Hygienic's products is a declaration of our product's conformance to all applicable EU provisions and the successful completion of the appropriate conformity assessment procedures.

Frequently Asked Questions

A hygienic pump is used in systems where cleanliness is vital to the product being pumped, such as food products, beverages, and pharmaceuticals. Hygienic pumps need to be able to be cleaned and sanitized on a regular basis and must be able to handle liquids gently. Indications that a pump is considered hygienic include certification of being an ATEX pump as well as other certifications.

The Viking hygienic pump with the highest pressure rating is our TRA®20 Series at 500 PSI. We encourage potential customers to contact their local distributor to discuss your specific application needs.

Viking's hygienic positive displacement pump products are manufactured both in Cedar Falls, Iowa, USA, and Eastbourne, UK.

Circumferential piston pumps handle high value shear sensitive liquids across hygienic applications where gentle handling, cleanability, and efficiency are paramount. Viking Pump Hygienic has a wide range of displacements with high pressure capabilities. It's ability to handle solids is excellent and has low shear characteristics across a wide range of product viscosities.

Rotary lobe pumps are the mainstay of many hygienic fluid handling applications where gentle handling & cleanability are of utmost importance. These pumps have a wide range of displacements, good solids handling capabilities, and low shear characteristics across a wide range of product viscosities. The non-contacting pumping principle for RLPs means no metal-on-metal contact, limiting pump wear regardless of product viscosity.

Centrifugal pumps can transfer large volumes of liquid, but efficiency and flow decrease rapidly as pressure and/or viscosity increases. Rotary pumps and circumferential piston pumps, on the other hand, offer higher efficiency wherein they move a consistent amount of liquid at a constant speed. They are gentle on liquids and have extremely low shear characteristics across a wide range of product viscosities.

Peristaltic pumps certainly have their place in the hygienic process, especially when handling fluids that will be infused with someone's blood (like IV fluid, for example). However, there are phases of the hygienic process that require gentle handling of the fluid being conveyed and the pulsation of a peristaltic pump could damage the product. That is why having a RL or CPP with consistent speed and flow is ideal, depending on the phase of production of the liquid.

| Pump Models | MAX Flow Rate (GPM) | MAX Flow Rate (m³/h) |

|---|---|---|

| Revolution® Series | 399 | 91 |

| TRA®10 & TRA®20 Series | 450 | 102 |

| Classic+ Series® / Multipump® Series |

832 | 182 |

| RTP® Series | 338 | 76.8 |

Click the pump model name to be routed to that pump's product description page.

Viking Pump Hygienic has a strong global network of distributors ready to assist you with all of your positive displacement pump and application questions. To contact your area distributor, visit vikingpump.com/contact, enter your zip code or country, and complete the contact form. A representative will be with you soon!

Pump product details can be found on their respective product pages. Above, you'll see the list of our product offerings; select "details" there to be taken to the product descriptions including pump performance information (capacity ranges, temperature ranges, operating pressure, etc.)

Related Videos

Drehkolben

Drehkolben

Drehkolben